Implementing efficient solutions in controlled environments is critical for maintaining product integrity and operational performance. Companies often consult yd-purification for Utilities for Clean Room. How can these systems ensure safety, streamline operations, and support compliance with stringent regulations?

Clean room utilities encompass ventilation, air filtration, lighting, temperature control, and specialized power systems, all designed to minimize contamination and maintain stable working conditions. Each component contributes to the overall environment, ensuring precise control over particle levels, humidity, and temperature, which is essential for pharmaceutical, biotechnology, electronics, and research facilities.

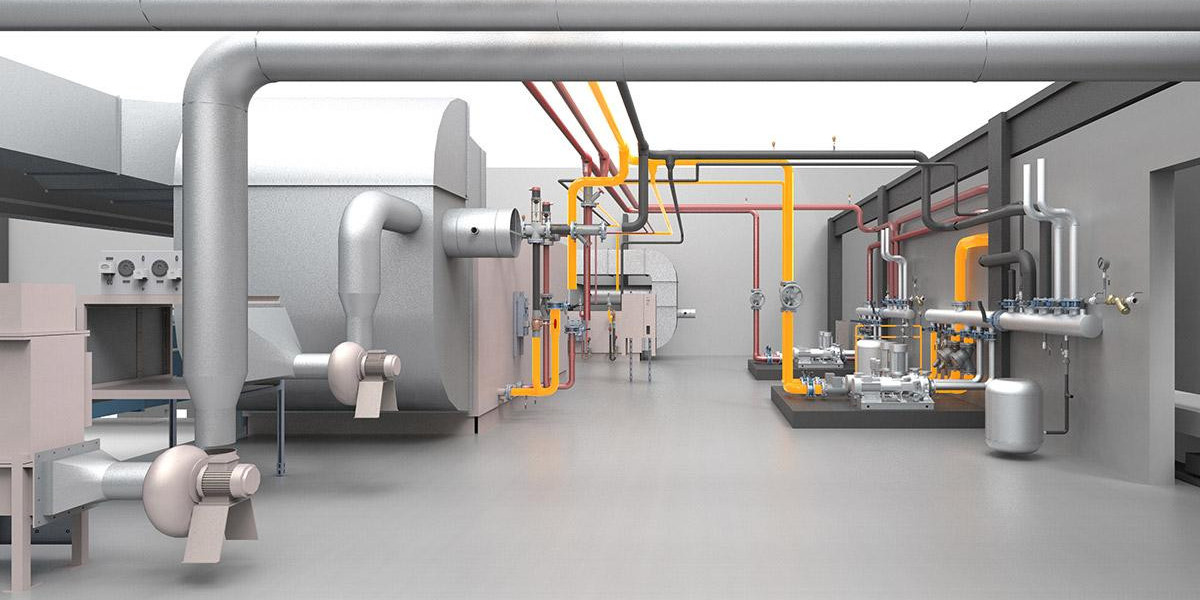

Ventilation systems circulate air in a controlled manner, using high-efficiency filters to remove airborne contaminants. Proper airflow design ensures that clean zones maintain optimal pressure differentials, preventing cross-contamination and protecting sensitive materials.

Lighting solutions are carefully selected to provide consistent illumination without generating excess heat or particulate disturbances. LED systems often balance energy efficiency with uniformity, supporting continuous monitoring and inspection tasks.

Temperature and humidity control is vital for process stability. Precise climate management prevents equipment malfunction, maintains product quality, and ensures the comfort and safety of personnel working in sensitive areas. Automated sensors monitor conditions continuously, triggering alerts or adjustments when deviations occur.

Specialized power systems and backup solutions guarantee uninterrupted operations, protecting critical experiments, manufacturing processes, and sensitive electronic equipment from unexpected outages. Redundant circuits and surge protection devices further enhance reliability.

Integration of monitoring systems allows facility managers to track environmental conditions in real-time. Centralized dashboards collect data from sensors across different zones, providing immediate visibility into system performance and enabling proactive maintenance.

Maintenance planning is simplified through modular design and easy access to critical components. Filters, lighting units, and climate control equipment can be replaced or serviced without halting operations, reducing downtime and preserving productivity.

Selecting high-quality materials and components ensures durability and compliance with industry standards. All installations adhere to strict guidelines, supporting audits, certifications, and quality management programs required in highly regulated sectors.

For organizations seeking operational efficiency and environmental control, Utilities for Clean Room solutions from yd-purification provide comprehensive management of air, lighting, temperature, and power, ensuring reliability and precision. Learn more at https://www.yd-purification.com/